SPECIALIZED SERVICES

Our specialized services are tailored to meet the unique and complex needs of clients across various industries. These services encompass advanced solutions that require specialized expertise, cutting-edge machine & technology, and a deep understanding of specific industry requirements. Whether it’s highly technical engineering or custom fabrication, we offer services designed to address challenges and drive innovation.

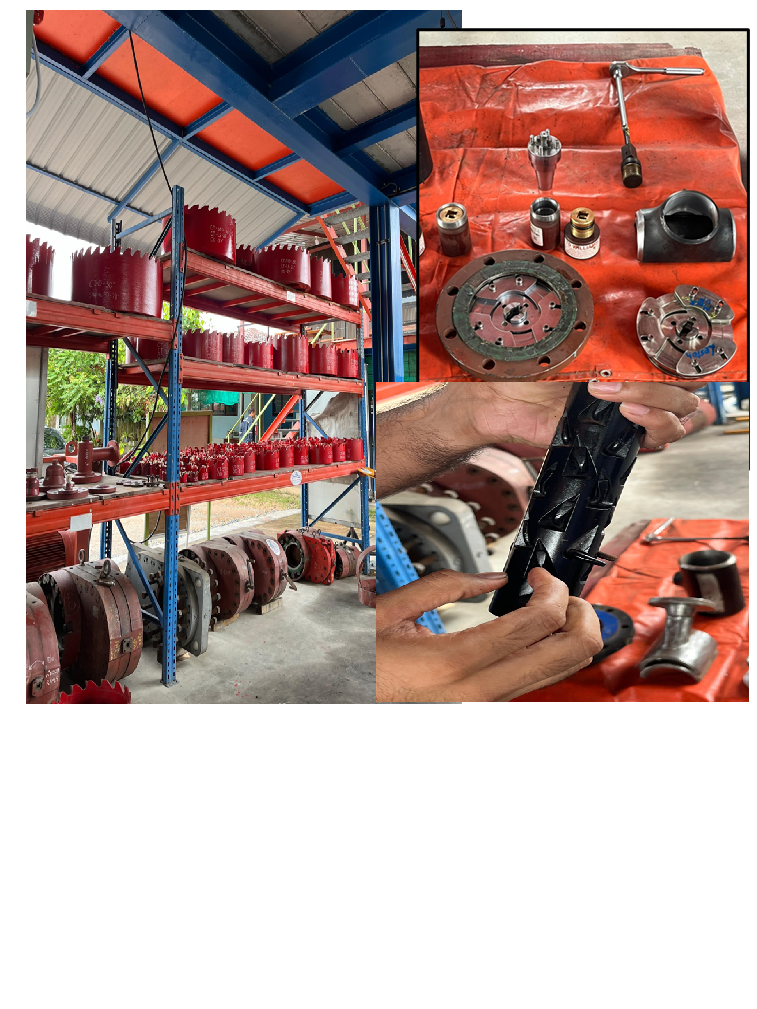

Hot Tapping:

Hot tapping is a method used to make a connection to an existing pipeline while it is

still in service and under pressure. This process allows for maintenance without disrupting the flow of the contents inside.

Hot tapping & Line stop

- Hot tapping with cutter, size of 2” up to 42”.

- Line stop from ½” to 30”.

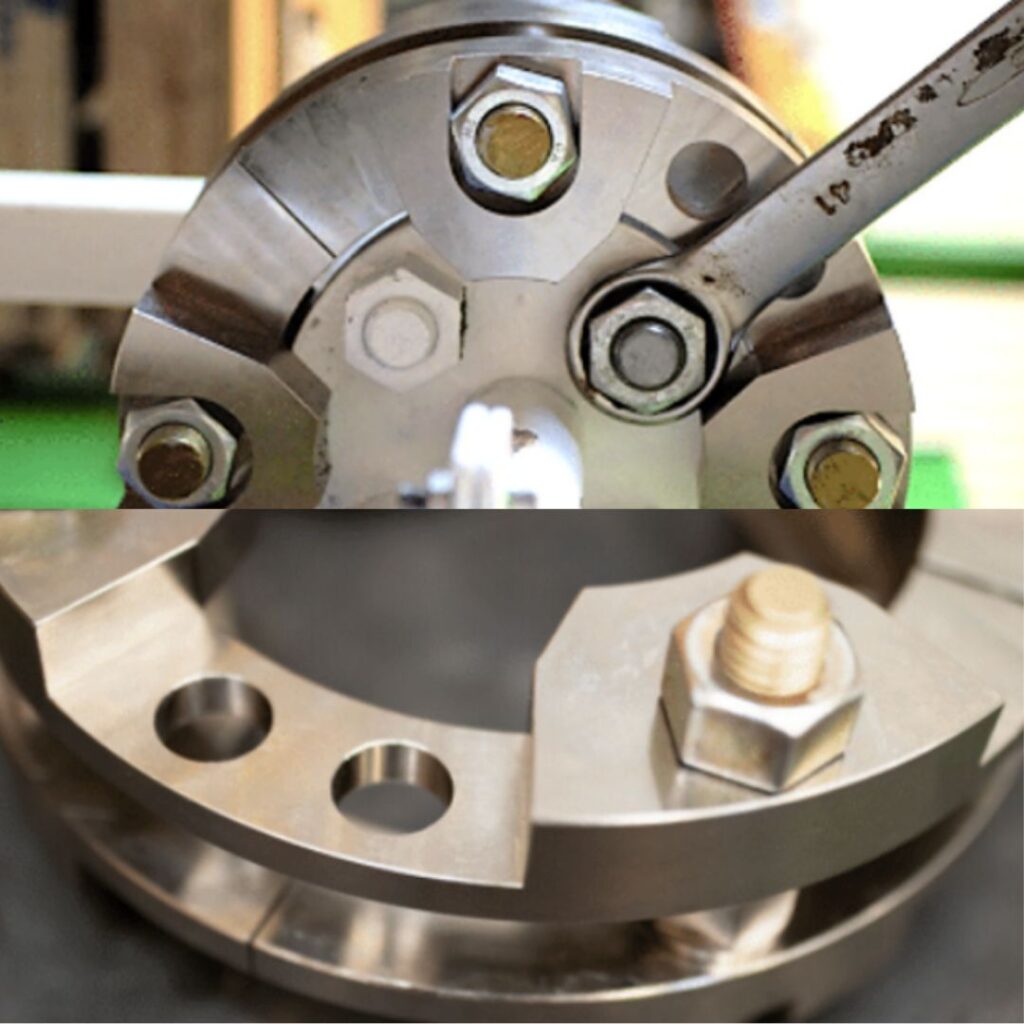

Bolting

Controlled bolting is a fundamental activity that takes place in every plant. It ensures theintegrity and reliability of equipment by applying precise torque specifications during thebolting process.

Methods of bolt tightening:

1.Hydraulic Bolt Tensioning

2.Hydraulic Torque Wrench

What is so good about controlled bolting?

- Consistency

- Safety

- Efficiency

- Reduced wear

- Easier maintenance

These advantages make controlled bolting a preferred choice in industries such as oil and gas, power generation, and manufacturing, where reliability and safety are paramount.

On Site Machining:

Our on-site machining services provide precision machining and repair solutions directly at the client’s location, minimizing downtime and reducing the need for equipment transportation. Our experienced technicians ensure quick and efficient service, restoring equipment to optimal performance with minimal disruption to operations.

- Flange resurfacing

Flange resurfacing is the process of restoring the flatness and smoothness of a flange surface to ensure a proper seal when connected to another flange or fitting. This is crucial in preventing leaks in piping systems.

- Cold Cutting & Bevelling

Our cold cutting and beveling services provide precise, safe, and efficient solutions for cutting and beveling pipes without generating heat. Using advanced equipment, we perform high-precision cuts and bevels that minimize thermal distortion, preserve material integrity, and ensure clean, accurate edges for welding and fitting.

Hot Bolting

What is Hot Bolting?

Hot bolting is the process of replacing or tightening bolts while the equipment remains in operation, under pressure, or temperature. It’s commonly used in industries like oil, gas, and petrochemicals.

What is Hot Bolting Clamp?

A specialized tool used to secure piping and equipment while removing and replacing the bolts. It provides additional safety by keeping the joint tight when a bolt is removed.

Why Hot Bolting is important?

- Ensure the system continues running during maintenance.

- Reduces downtime and production losses.