Why use Hydraulic Tensioners?

Specifying the use of hydraulic bolt tensioners has many benefits when compared to other tightening methods. These include :-

- Accuracy – Tensioner do not require the bolt or nut to be lubricated. Lubrication often introduces unknown that can impact accuracy which can increase bolt load scatter

- Multiple bolts tightened simultaneously – This ensures the joint is evenly closed and the gasket evenly loaded. Even gasket load significantly improves gasket performance.

- Speed – Because it is common to simultaneously tension multiple group of bolts, joints can be tensioned very quickly.

- Reliability – Tensioning only requires a robust cylinder to be pressurized.

- Quality Assurance – Bolt Tensioning Process is highly reliable and repeatable.

- Environmental considerations – Uniform bolt loading gives even gasket loads minimizing risk of emissions from bolt joints.

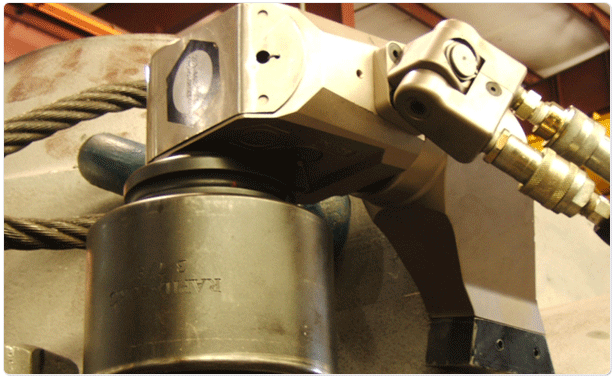

- Hydraulic Torque Wrench – Specifically designed for extremely low height acess applications, our Hydraulic Torque Wrench offers a cost efficient option to handle a wide range of bolt tightening and break-out needs.

Our standard Square Drive Series

Features different tools with capacities ranging from 100 to 60,000 lbf.ft of torque using a 10,000 p.s.i hydraulic pump. Our robust and lightweight aluminum body completely encloses the drive train assembly keeping the crucial lubricant inside the tool while significantly reducing the opportunity for outside elements to contaminate inside the tool

Low profile hydraulic ratchet wrenches

Require minimum clearance while applying torque on the same plane as the nut, providing a marked improvement over square drive socket wrenches. Our design breakthrough reduces the overall dimensions of the inline ratcheting head allowing it to fit almost every application. Our standard Hydraulic Cylinder/Link Series features seven different